Gallery

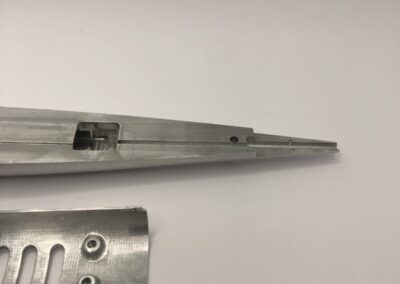

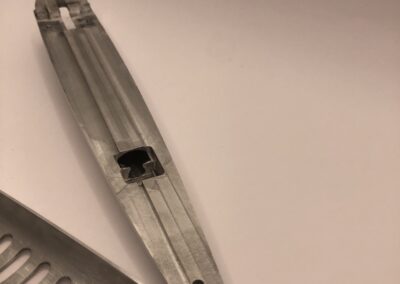

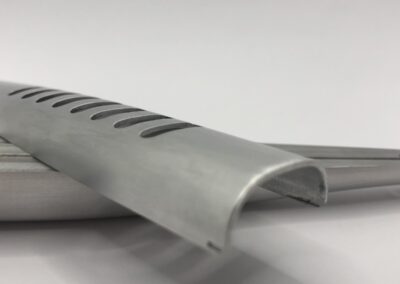

Most of the parts you see on our site were made for the medical industry and other high caliber industries. We have machined a high range of materials like delrin, aluminum, mild steel, stainless, titanium, and many more. These images are of parts that have gone to aerospace companies that have sent these parts into space and into the air. They have gone to prosthetic companies that have replaced human bones with the parts we’ve made. Some of these have even been for sewing machines that we have built whole assemblies for. A lot of these bigger aluminum parts were made for a company that makes snow making guns that you can now find in big ski resorts like Park City and all around the world. Quality Machine has made a huge impact on many different industries by helping them with their manufacturing processes. We have been able to simplify the way things have been made to save time and money.

Starting off, Shane the owner created relationships with engineers at AbbottAbbott Laboratories then decided to start his own shop and instantly started doing medical jobs. He got into different companies as these engineers moved around to different companies. Many of the parts you see here we built and machined to the medical industry. Medical equipment can range over a huge number of different applications. Quality Machine has participated in making big x-ray machines. If you go to the dentist in the states and have to get your teeth x-ray’d, if they’re using an x-ray where you’re standing up, chances are Quality Machine made many of the parts in that assembly. We have also had a hand in making parts for the airport x-rays that spin around you when you go through security. One day Shane was on vacation on the other side of the world and came across someone that had prosthetic knee support that he machined at Quality Machine.

A lot of these parts are older technology that looks new but is actually from around 20 years ago. Over time we have seen the industry evolve especially when it comes to medicine. The way that doctors do things now is very different to how they did things when the company started. For example the prosthetic knees we would make used to go outside the body and now they actually go inside to replace the knee bones instead of just supporting them. As technology has gotten better in the machining industry these medical features have become more accessible to the public and have become cheaper. As time has gone on machine shops like Quality Machine has had to learn how to do harder things. When technology gets better things tend to get smaller and we have to figure out how to hold these parts and actually machine them. Not too long ago a computer would barely fit in a large room. Now we can fit a computer just as powerful in our pockets. The machining industry has played the biggest part in this as it has learned to machine the same components a lot smaller.

When you think of manufacturing in America you think of Detroit or areas on the East coast. A lot of vehicle and military manufacturing happens on that side of the country. When it comes to medicine most of it happens on the Weston the West coast. All these intense medical parts you see on our website were made for companies on the West coast and MidwestMidwest parts of America. If you drive through Salt Lake on the west side of I-15 you will find countless numbers of companies that are contributing to making the medical industry better. If you drive up near the University of Utah you will find many instrumentation companies that a lot of these parts have been done for. Also in that area is Sarcos, aSarcos, a robotics company. We have made complicated aluminum parts that have been sent around the world to clean oil out of the ocean.

People often ask us why we do so much work for the medical industry when it’s a lot easier to get work from the government or weaponry companies. One big reason we love medicine is that we love to help people. Being able to help people live longer and enjoy their life more has been a huge blessing. Seeing the components we make go to helping someone, words can’t explain how that feels. When most people look at these parts we’ve built they see just a random shape made out of a random type of metal. When we look at these parts we see progress in technology that is going to save many lives and help countless numbers of people. Another reason we do medical work is that when we treat our customers well we want to be treated well in return. We have met the coolest people working for all these different companies. We hope that we can continue to grow to make more and more of these parts to bless as many people as we can.

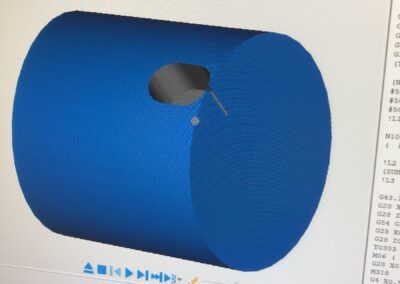

When you look at a print the first thing you ask yourself is how am I going to hold this part. Some of these complicated funny shaped parts you see here, we have shown these finished parts to some experienced machinists that couldn’t figure out how we made them. Quality Machine can machine pretty much anything someone can draw on a print. We don’t like to say no to jobs. We love it when engineers come to us with the problems they’re having in regard to machining a part. We like figuring out how to make a part nobody else can make and doing it for a fair price. The way we’ve been able to outsmart the competition is through 60 years of machining tricks that’s embedded in this company.

The proof is in the pudding. You can see by looking at these parts that when it comes to small to medium-sized parts there’s almost nothing we can’t do. We are asking new companies that we haven’t done work to put us to the test and we will give you 50% off on all labor for the first job we bid for you. Rather than talking about it let us show you what we can do.